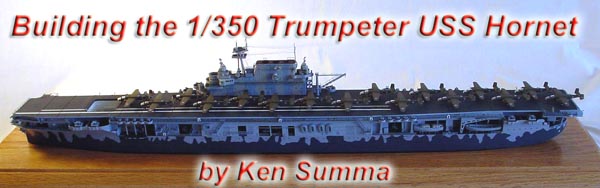

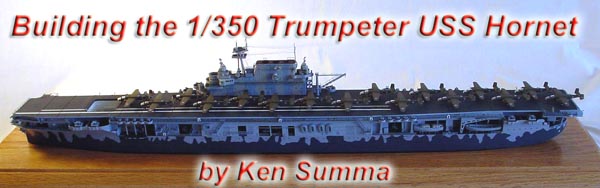

| The USS Hornet, CV-8, was laid down in

September 1939 as the third member of the Yorktown-class aircraft carriers.

She was commissioned in October 1941 and spent the next six months working

up in the Atlantic. The ship is best remembered for the celebrated

Doolittle Raid on Japan in April 1942. For that raid, she embarked

sixteen B-25s which were flown off the deck about 600 miles from Japan.

Her normal compliment of aircraft was stowed below in the hangar deck.

Although the raid caused minimal damage, the propaganda value of the raid

was immeasurable. The Hornet participated at the battle of Midway,

but was sunk at the Battle of Santa Cruz on 27 October 1942. She

was hit by four bombs and sixteen torpedoes from both US and Japanese vessels. |

|

|

| This article is a follow-up to an

in-box review done on Trumpeter’s USS Hornet kit. This buildup

incorporates a number of aftermarket accessories that enhanced the final

appearance of the kit. |

click to

enlarge images |

|

|

|

For this build, I incorporated five different photo-etch

(PE) sets, three Gold Medal Models (GMM) and two White Ensign Model (WEM)

sets. The primary PE set is the:

-

GMM Hornet detail set (GMM

350-21) contains railing, ladders, island details, radar, cranes, and

details for the boats and anti-aircraft weapons.

-

GMM’s Gold Plus Hornet Extra Details set (GMM

350-21A) features perforated catwalks, more boat details, windbreaks,

and LSO platforms.

-

The airgroup was outfitted with PE from GMM’WW2 USN Aircraft Parts (GMM

350-26).

-

The hangar deck interior fittings and bulkheads were assembled with WEM’s

1/350 USS Hornet Interior

Fittings and Accessories set.

-

Finally, WEM’s 1/350 USS Hornet “The Airwing” set (PE

3526) was used for aircraft interiors, bomb carts, torpedo carts, and

other miscellaneous deck equipment.

How these sets were integrated into the model will be discussed below. |

| The kit itself looks great in the box. The plastic parts are

molded without flaw, although there was some flash present on some parts.

The main difficulty that I ran into with this kit was the fit of the hangar

deck walls. This is most likely the product of panagraphing the master

from a resin kit. This theory is bolstered by the misshapen bow and

minor inaccuracies inherent with the original resin pattern. |

|

| I started the model by detailing the hull. The bow

is not correctly shaped, having a “tug-boat” appearance that is most noticeable

when built as a full-hull model. Instead of reshaping bow, I decided

to live with a waterline model since the inaccuracy is less apparent.

Missing from the hull is the armor belt, which I add using strip styrene.

I also drilled out the portholes and hawspipes for the anchors. Using

a technique from Keith Bender, I added hull plating by building up layers

of paint on the hull. The hull is cleanly molded but is devoid of

detail. To give the hull more life, I added boat booms and fuel lines.

I then applied the Modified Measure 12 paint scheme. Hull number

decals from Classic Warships completed the hull work.

The hangar deck and forecastle were added to the hull along with various

deck fittings. I sanded off the molded on anchor chain to make room

for jewelry chain. The next step was to add on the hangar deck walls.

Before I did this, I cut out the roller curtains so that the interior of

the hangar deck could be seen. Once completed, I added these parts

to the hull. Be careful and test fit these as the starboard kit parts

don’t fit well. I had a lot of problems with parts A4 and A12 that

would later complicated adding GMM’s PE catwalks. I would suggest

adding the hangar deck walls by starting forward and working aft.

|

| The hangar deck interior was built using WEM’s Interior

Fittings and Accessories set. This set comprises PE overhead girders

and vents and templates for assembling the hangar deck walls. Assembly

of the overhead girders was straightforward and their installation inside

the hangar deck was perfect once the main longitudinal truss aft was cut

short to fit properly. I used the templates in the set to assemble

the interior walls. I added bits of styrene and spare PE doors and

fittings to add detail to the interior. The fit of my scratchbuilt

walls was right-on. |

|

|

|

|

| Once painted, I added the interior walls to the hangar

deck. Before the girders were installed, the F4Fs, TDBs, and SBDs

that made up the airwing were emplaced with white glue. Since I did

not build an entire airwing, I liberally arranged the aircraft to give

the illusion of a full compliment of aircraft.

|

| For my build, I assembled 46 aircraft – 12 F4F Wildcats,

12 TBD Devastators, 6 SBDs, and 16 B-25s. Each aircraft is in itself

a mini-kit, with separate wings, fuselages, nacelles, propellers, and landing

gear. PE brass from GMM’s USN aircraft set and WEM

“The Airwing” set added extra details to each. For the USN aircraft,

I used decals provided in GMM’s 1/350 WW2 USN

Aircraft Insignia Decals (GMM 350-6D) since the decals provided in

the kit are incorrect for April 1942. At that time, the US Navy still

had the red “meatball” in the center of the star. The decals settled

down well with SolvasetTM. Testor’s Dullcoat sealed the decals. |

|

|

| The aircraft are finely molded in plastic with exceptional detail.

Even the propellers look incredible and PE equivalents may not be required.

All the aircraft were assembled as indicated by the instructions.

The seams required minor filling with superglue and sanding with 400-grit

sandpaper. |

|

|

The F4F Wildcats

|

| The F4F Wildcats are cool little aircraft when assembled.

All of mine were assembled with the wings folded, although there is option

to have the wings extended. Be careful with the horizontal stabilizers,

as they did not fit well into the guide holes in the fuselage. GMM

provides parts for the complex landing gear arrangement. For two

aircraft, I hollowed out the cockpit and added parts from the WEM PE set.

These extras included an instrument panel, floor, seat, and control

stick. Although the PE parts were tiny, careful handling and placement

led to good results.

|

|

The SBD Dauntless Dive Bombers

|

| The SBDs were easy to assemble. The fit was good

except at the wing root. To hide the seam, I used a combination of

white glue and paint since sanding would have damaged some of the intricate

panel lines. For one aircraft, I hollowed out the cockpit and installed

WEM interior details made up of an instrument panel, two seats, bulkhead,

floor, control stick, and machine gun. The result, after cutting

the canopy into two sections, was astonishing. If I had more time,

I would added interior details to all the aircraft.

|

|

The TBD Torpedo Bombers

|

| Like the SBDs, the TBDs were a cinch to assemble but had

a noticeable gap in the wing root to fuselage joint. I installed

WEM’s cockpit details to one aircraft and am impressed by how much extra

it adds to the aircraft. WEM provides an instrument panel, seats,

cockpit floor, bulkhead, and machine gun.

|

| The B-25 US Army Bombers |

| Assembly of the sixteen B-25s was straightforward, although

a prominent seam in the fuselage required filling. Of note, the underside

turret needs to be removed since these were not on the aircraft flown off

the Hornet. Missing as well are the two dorsal turret guns on the

dorsal turret and the tail guns. I left the latter off and used fine

plastic rod for the former. After painting and assembly, I applied

General Quarters Decals fantastic set of decals. The set includes

insignias, correct aircraft numbers, red fuselage stripe, “US ARMY” decals,

and nose-art for six aircraft – including the “Ruptured Duck” of Thirty

Seconds Over Tokyo fame. With references from the Internet, I was

able to place each aircraft in the proper sequence.

|

| I completed the hull by adding GMM’s excellent hose reels,

ladders, railings, and cranes. All assembly required for these fittings

was easy since GMM has etched in folding lines. The catwalks from

GMM are an incredible addition to the model and are worth purchasing.

These went on easily and accepted the 20 mm guns and directors with minimal

trouble. Speaking of the weapons fit, GMM provides gun shields, sights,

elevation wheels, and shoulder harness for the 20 mm weapons. I replaced

the 5”/38 plastic barrels with brass tubing and added railing to these

mounts. The 1.1” “Chicago Pianos” were Classic Warships parts that

are far superior to the kit parts. Once painted, these weapons were

added to the model. The boats were detailed with more GMM PE parts. |

|

|

|

|

| The flight deck comes in three pieces and shows good planking

detail. The deck is, however, devoid of arresting wires, pulleys,

and crash barriers. Both GMM and WEM provide these parts in their

PE sets. I added the GMM parts to the deck before painting.

I then mounted the deck onto the hull. Mating these creates a couple

of seams that only careful filling and sanding will eliminate without scaring

the adjacent planking detail. I chose to use white glue as a filler

material.

|

| The final step in building the hull was construction of the island.

This was simple to assemble but required some filler. GMM’s PE details

enhanced the island’s appearance with catwalks, radars, ladders, and yardarms

for the masts. After painting, I installed the rigging using monofilament

line. The island was attached to the hull and the model mounted to

its base. |

|

|

|

My USS Hornet was one complicated model especially since I used five

different PE sets, three separate decal sets, and scratchbuilt a host of

missing detail. The end product, which took me more than 6 months

of work (not consistently though), is a wonderful addition to my collection.

All of the PE sets that I used were easy to work with and did not cause

any assembly problems. Aside from some inaccuracies in the kit and

fit problems, this was one enjoyable build.

The photoetch sets were obtained through Gold Medal Models and White

Ensign Models. The decals were courtesy of GMM, Classic Warships,

and General Quarters Decals.

Links:

|

|