| Back to Menu |

|

|

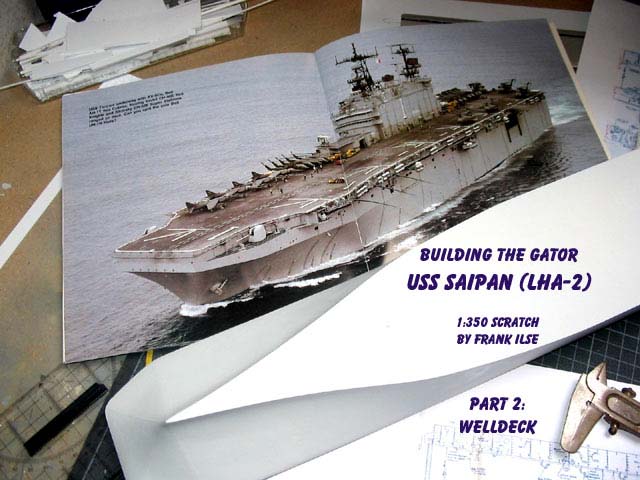

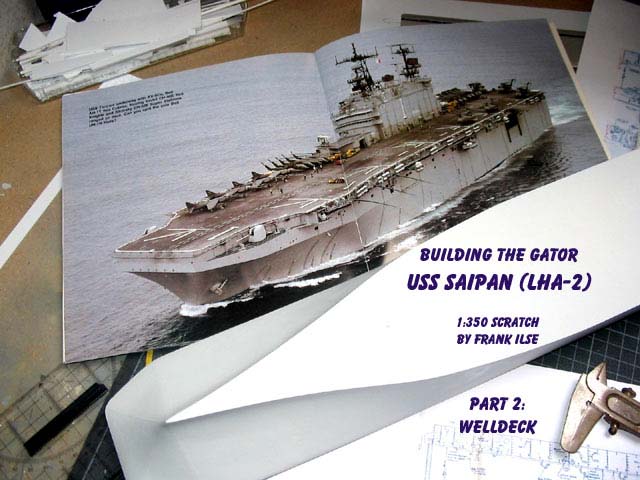

| Having started the buildup feature of my 1/350 scale gator

USS Saipan with the basic construction of hull and island, I now will proceed

with the first component to be completed: the well deck. I detailed it

as much as possible because it will be visible later on, although the hangar

bay and the flight deck are above. But I found a way to make them free

to move later on. But first, some data. |

click images

to enlarge |

|

|

|

|

| The ships of the Tarawa class are swimming Heliports with an additional

feature. Like a submarine they can go down controlled. To a certain extent

that is. Huge pumps and flood valves fill ballast tanks that enable the

ship to lower its stern about eight to nine feet. Through the opened gate

at the ship's stern water flows into the well deck. |

|

|

|

| This technique enables the Marines to board the landing craft with

dry feet as long as the well deck is dry. After boarding, the ship's crew

floods the deck and the landing craft, whether LCU (Landing Craft Utility)

or LCAC (Landing Craft Air Cushion) leaves the well deck via stern gate.

The United States developed this technique during WWII. LSD (Landing ships

dock) were introduced to the amphibious operations from 1944 on to the

end of the war, featuring a similar construction. A modern amphibious force

incorporates an LHA, Tarawa class, or an LHD Wasp class as core and flagship.

Two LSDs, frigates, destroyers and an Aegis-cruiser are normally added.

USS Saipan is currently the core of Phibron 2. She sails together with

USS Trenton LPD 14, USS Oak Hill LSD 51, USS Hue City CG 66, USS The Sullivans

DDG 68 and USS Underwood FFG 36. Homeported in Norfolk, Virginia, the ship’s

motto is Ready to Strike. |

|

|

|

| Modelling a well deck can be finger-twisting and has a lot to do with

adjusting, aligning and test fitting. For two main reasons: the huge deck

in 1/350 scale shrinks to mere 30 centimetres lengh, 9.5 centimetres wide

and only 2.7 centimetres high between decks. And I wanted it to be visible.... |

|

|

|

| Construction goes in basically four steps: sidewalks, middle complex,

floor and ceiling-construction. If you like, you can add tanks and personnel

as part five. Here we go- |

|

|

|

| First of all you draw some reference lines on the inside of the hull,

port and starboard side. They mark the well deck’s height. This was followed

by cutting the inner sidewalls from styrene-sheet. I used 1 mm basically

throughout the well deck’s construction. Behind the inner sidewalls are

walkways for the crew handling the landing craft. From stern to bow there

are different stations marked to make orientation for the crews of landing

craft and amphib-tanks easier. The walkways connect to the well deck via

large oval openings that hat to be cut out next. I made a template to mark

the positions and carefully started cutting out the ovals on port side.

What a tedious job. So I tried another method on starboard side using an

eight millimetre drill for the rounded sides of my ovals. It worked well

in a split of time. Scratchbuilding really is a dynamic process. |

|

|

|

| Right under the oval openings I glued another strip of styrene sheet

in a right angle to the sidewall, my walkway. The openings were detailed

with railing from a generic GMM 1/350 photoetch fret, chocks (fairleads

- for the British), and bollards. Two additional strips were cut as the

walkways backwalls, detailed with fire hoses and doors from a GMM fret

and 0.25 mm styrene rod as piping. Everything was airbrushed in Model Master

Light Gull Grey, even lighted with white, as the well deck areas are in

a very light grey, even white color. The fire hoses were painted red. |

|

|

|

| My Saipan is a real multimedia kit. I use plastic, metal, resin – and

wood. The well deck’s inner walls are planked with wood to avoid damage

from bumping LCU and tanks. This planking is about 0.5 millimetres thick

in 1/350 scale. I used mahogany strips I had left from an historic ship

project and glued them to the sides with superglue. I marked the plank

structure with a hard pencil and painted some planks in white, orange,

red or yellow according to photos of well decks I found on the US Navy’s

official website. |

|

|

|

| And now I started to go nuts. Right above the wood planks is a line

of mooring-eyebolts. Leave them off!! shouted a voice inside of me. Go

ahead – do it!! whispered another. Well, there was this GMM-fret, I had

used for my Trumpeter Liberty ship and there were lots of eyebolts left

on it. Hmmm.... I started on one sidewall, in the evening, after a glass

of wine or two – it worked! Three days later I had two sidewalls with wood

covering and eyebolts. |

|

|

|

| Step two is the well deck’s middle construction. The Tarawa successor,

the Wasp class, no longer has this partition, because without they can

take more LCAC aboard. The partition’s plan view was easily taken from

my plans, but the side view is a guess I got from several pictures from

the USN homepage and from books, lacking correct plans of it. The partition

is a simple built, constructed from various pieces of 1mm styrene sheet.

After the basic construction everything was filled and sanded to shape

and doors and hose reels from a GMM fret were added. Airbrushing in light

gull grey lighted with white followed. The middle partition got its wooden

planking too and there were even enough eyebolts left for further detailing.

I set everything aside and headed on to step three: |

|

|

|

| The floor construction. The well deck floor extends for two thirds

of the deck on an even level and following the way to the ships bow rises

to a higher one. This rise is done by a ramp. The floor has the even structure

typical of a steel deck and shows rails to tie the Marine-vehicles. The

ramp has a rippled structure. |

|

|

|

| First I cut a floor plate, 1mm styrene, to shape and glued it into

place. With a sharp pencil I marked the position of the tiedown rails and

the partition. I glued down the rails, 0.25x0.5 mm styrene strips, just

up to the ramp and painted the floor in gunship grey (Modelmaster). After

the paint was dry I glued the sidewalls into place. |

|

|

|

| The rised part of the well deck’s floor got a substructure of 7x3 mm

strips. The strips were set in a way that the middle construction was fitting

tight in between the strips. I cut a piece of styrene sheet to shape and

sealed that part of the floor. I added the ramps and lacking tiedown rails

and painted everything in gunship grey. |

|

|

|

| If you want to take a look at the well deck later, one way will be

through the open stern gate. Doing so, you would squarely look at a bare

white or grey wall, because I will not go into further detailing the ships

interior on that level. This annoyed me - but I found a way out. I looked

for a picture that shows this part of the well deck looking forward and

found one, just one, to be frank, on the US Navy’s website of course. I

cropped a part of that picture using photoshop and with the help of my

graphics program I mirrored and cut it to fit my well deck wall. Voila

– a wallpaper. I glued it into place and now the view goes into distant

compartments. Finally the middle construction was glued into place and

I was ready for the ceiling. |

|

|

|

| There is a little catch waiting for you. The well dock’s side walls

are connected with steel I-beams that carry the rails for the cranes that

run under the ceiling. I had to find a way to mount the rails to the beams

that afterwards had to be fixed between the siedewalls. As a solution I

took a piece of transparent styrene and cut it to ceiling shape. This was

laid onto the sidewalls. Then I marked the beam positions with an overhead

marker from ABOVE. I cut the beams to size and glued them to my ceiling

from BELOW. Checked the correct fit by laying the ceiling onto the sidewalls

frequently. When everything fitted into place I took the ceiling and glued

the crane rails to the beams from BELOW, using 0.5x0.5 profiles. |

|

|

|

| Now it was time to close the well deck, but I wanted to bring it to

life before. I had already purchased some vehicles from Skytrex, a British

company that provides our wargaming friends: AAVP7 amphib tanks, Bradleys

and LAVs. I airbrushed them in a sand tone, gave them an umbra wash and

highlighted the details drybrushing in a very light sand. I added about

25 figures from L’Arsenal and Preiser, painted as sailors and Marines.

The personnel and vehicles were scattered throughout the well deck as if

Marines were preparing for debarking. |

|

|

|

| As a final step I installed the ceiling by glueing styrene strips from

ABOVE and fixing the transparent ceiling that way and in the same way getting

a substructure for the hangar bay – that is to follow as one of the next

steps in this built. |

|

|

|

|

|