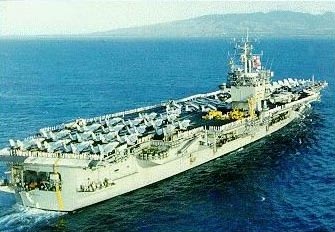

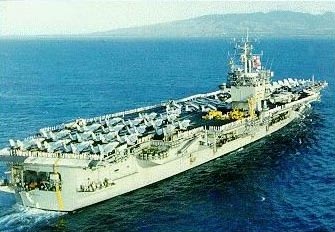

USS Enterprise CVN-65

In 1/350 Scale

by Kelly Quirk

Commissioned in 1961 The USS Enterprise was the first Nuclear Powered

Aircraft Carrier. This month Kelly Quirk shows us how he built his Carrier,

the centerpiece of his contest winning diorama featuring the Big E and

the USS New Jersey underway exchanging supplies. We start with the Tamiya

1/350 plastic kit, a great kit to start with, but

a lot of detail needs to be added. A kit this size should come with

at least a basic hangar deck. But, it is a detailers dream.

I don't think you can ever actually finish this kit, there is always something

more you can add to it. The basic additions I made were of course

the hangar deck, I also

made an LSO platform, and I detailed out the

bare catwalks.

| Since this would be a waterline model the lower hull was removed with a Dremel tool. The hanger bay is completely scratchbuilt from sheet styrene. The tie down spots were marked and drilled out. Girders, pipes, various boxes, etc. were added throughout, made from bits of plastic, spare parts, and tubing. On the ceiling, individual light fixtures were made from punched styrene, and a fiber optic light was glued into position at each fixture. |  |

|

||

| Three small bulbs were installed to help with general lighting. Drop tanks racks were scratchbuilt, and resin cast drop tanks were installed. Aircraft were modified for the hanger deck, note the folded wings, repair ladders, tool boxes, etc. Pallets of cargo and ordnance were scratchbuilt. The forklifts were scratchbuilt and a couple of resin cast tow mules were put in place. The firewall door and elevator doors were added. After adding various decals and figures the hanger deck was complete. |  |

|

||

| On the hull I added the three prominent holes in the bow by gluing styrene disks in the proper location, then drilling them out. I also drilled out the small portholes on the lip of the bow, and added covers in the open position. The sponsons were all glued in place, and the gaps were filled. Photoetched railings, doors, and ladders were all added at the proper locations. On the starboard rear sponson, the hole for the missile launcher was filled as the Enterprise did not carry a launcher there. A chaff dispenser was also added next to the Phalanx gun on the port side. The ships crane was totally rebuilt. |  |

|

||

|

Pallets of

Deck Cargo in process |

|

||

| The deck sections were glued together and the gaps were sealed and sanded I filled the gaps between the deck sections with layers of superglue and baking soda. Be very careful sanding the seam, you want it to be smooth, yet still match the rest of the deck. Before sanding, I drilled out the deck tie down spots around the seams so that detail wouldn't be lost. The catwalks were detailed out with hose reels, hatches, foam dispensers, and other bits. Jet Blast Deflectors were scribed with accurate panels. Deck markings are a mix of paint and decals, and each tie down point was hand painted by dipping a toothpick in very light grey paint, and transferring a dot of paint to the spot. Using pure white looked too bright to me. |  |

|

||

| The island superstructure was built, some styrene walls were added, and detailed with Photoetched cage ladders, radar's, stairs, and railings. The mast received Photoetched yardarms and railings. Accurate decals from Dunagain Decals were applied. Rigging was made using the stretched sprue method. |  |

|

||

| All aircraft were modified. They all received landing gear doors, pylons, resin cast drop tanks, and repositioned wings. All exhaust nozzles were drilled out. Many F-18 Hornets and F-14 Tomcats have open canopies. These were made by first filing away the molded on canopy, then scratchbuilt ejection seats and consoles were added. A thermoformed canopy was made, cut to shape, painted and glued in place. See the Airwing buildup article for details |  |

|

||

| Various Hornets also have repositioned tailplanes, dropped flaps, weapons, and boarding ladders. Refueling probes were added to the Intruders and Prowlers, as well as a weapon load on some of the Intruders. The cargo door was cut out of on of the Sea Kings. |  |

|

||

| The two CH-53's on the stern came from White Ensign Models, I thought it would look cool to add a couple visiting Sea Stallions. One of them had the cargo access area filed out, and a set of steps was added. Refueling booms were added from stretched sprue. I applied decals made by Gold Medal Models to all aircraft. |  |

|

||

| The tow mules were painted and decals were applied, tow bars were made from wire, and everything was finally glued in place. The Tilley was detailed with a push blade, cables and hook. There are approximately 500 hand painted figures glued in various places on two ships. |  |

|

||

| Take a look inside the hanger (photo's somewhat out of focus) | ||||

| Editors note: Kelly tells me that this project represents over nine months of work to complete. It probably would not have been possible had he not received help from his lovely wife Leslie. |  |

|

||

Links: