| In the 1960’s the term “Overkill” was coined to describe

the ability of the 2 super powers, the United States of America and the

Union of Soviet Socialist Republics to destroy each other not only once

but many times over and over again; due to the sheer number of nuclear

devices each of them had amassed during the years.

But when I look at this boat, I’m pretty sure that this was where this

cruel term originated. The designer wanted it to steam abeam an enemy to

stick its deployed spar torpedo into his lower hull s and exploding it;

then, just to make sure, ram him with this epic bow , and if that poor

enemy, foolhardy as he could be, still refused to die a glorious death,

complete the annihilation with , at this time the largest gun ever put

onto a ship , a 15” Dahlgreen smoothbore gun!

Concerning those 4 Gatling guns alongside on the railing, well think

of them as some kind of garnish, which could be used in the highly unlikeable

event when the surviving crew of the previously violated ship were sufficiently

brave or foolhardy enough to try and board the vessel that caused such

torment.

....if that is not what one would call overkill,.... nothing is!

And for any landlubbers reading, just in case you are still wondering:

During the Napoleonic wars, which ended in 1815, a 42pdr gun was considered

a real ship killer, as the designation tells, this gun fired a cannon ball

weighting 42 pounds,

while a 15” Dahlgreen fired a projectile weighting 352 lbs.!

Just try to imagine what one solid hit with that monster did to a wooden

ship; if the term “mincemeat” comes into your mind, you’re on the right

way.

A spar torpedo was in fact what we today would call a mine.

But back in those glory days it was an explosive charge on the tip of

a spar which was rammed into your enemies’ ship hull, far below the waterline

where it was un-armoured and therefore highly vulnerable.

On contact it would explode, ripping the guts out of almost any vessel.

The damage such a “torpedo” caused was in most cases fatal .

And finally, ramming a ship! Granted this is a very, very desperate

measure. Even for the most powerful and most sturdy ships ever built ramming

was always the very last option during an attack. The damage caused by

ramming with high speed was disastrous, not only were the ships walls ripped

wide open, frames were dislocated, seams all over the ship cracked open

because of the stress put onto them, large and heavy machinery was dislodged

and caused even more carnage, steam and fuel pipes were cracked and could

easily cause large fires, in the worst case a keel was ripped apart which

spelled certain doom to any ship, in other words total chaos! But the real

problem was the fact that such tremendous damage was not only created on

the rammed enemy vessel but on your own too, because of the sheer masses

involved in such a crash.

But this very ship here was playing in a different league or it should

have, perhaps, maybe, who knows? As a matter of fact the designer of this

maritime nightmare did not stop after creating the mother of all armaments;

no he also wanted the ship to have the best possible propulsion system,

it should be faster and more agile than anything else around. Well it was

fast, sort of…

The solution for the designers idea was a so called Fowler wheel, a

let’s call it very special propeller. As already mentioned the ship should

have been able not only to outrun any enemy ship but to outmaneuver them

too. At least it did the last thing, it could turn on a dime but it never

was able to outrun anything, at least not a warship, nor a merchantmen,

it was so dead slow it could not even run away from a rowboat, with a crew

consisting purely of landlubbers, with no arms and no legs and just to

make sure no oars as well! That special propeller was a complete disaster

and even after some extensive testing the problem could not be solved,

sometime later a “far better” solution was found in the form of an even

more special propeller, after some more money was spent and that new prop

installed the result was …yup, you got it, still the same! The boat could

outturn anyone, even itself but outrun… forget it!

Just the attempt to leave the harbour turned into an epic voyage.

So its armament was second to none but did I mention it was slow?

They should have named it USS Ridiculous.... instead of USS Alarm..?

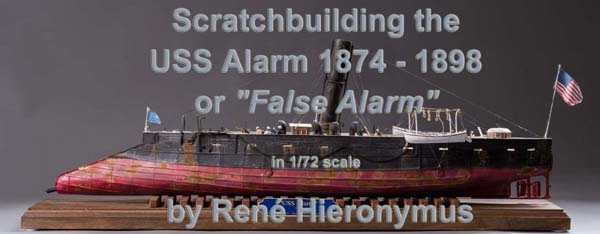

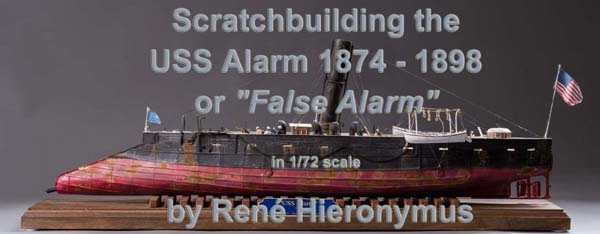

So why on earth you may ask did I build this monstrosity?

Hey, take a look at it, this thing is so damn cool, so awesome, so outlandish

I had to build it!

|