|

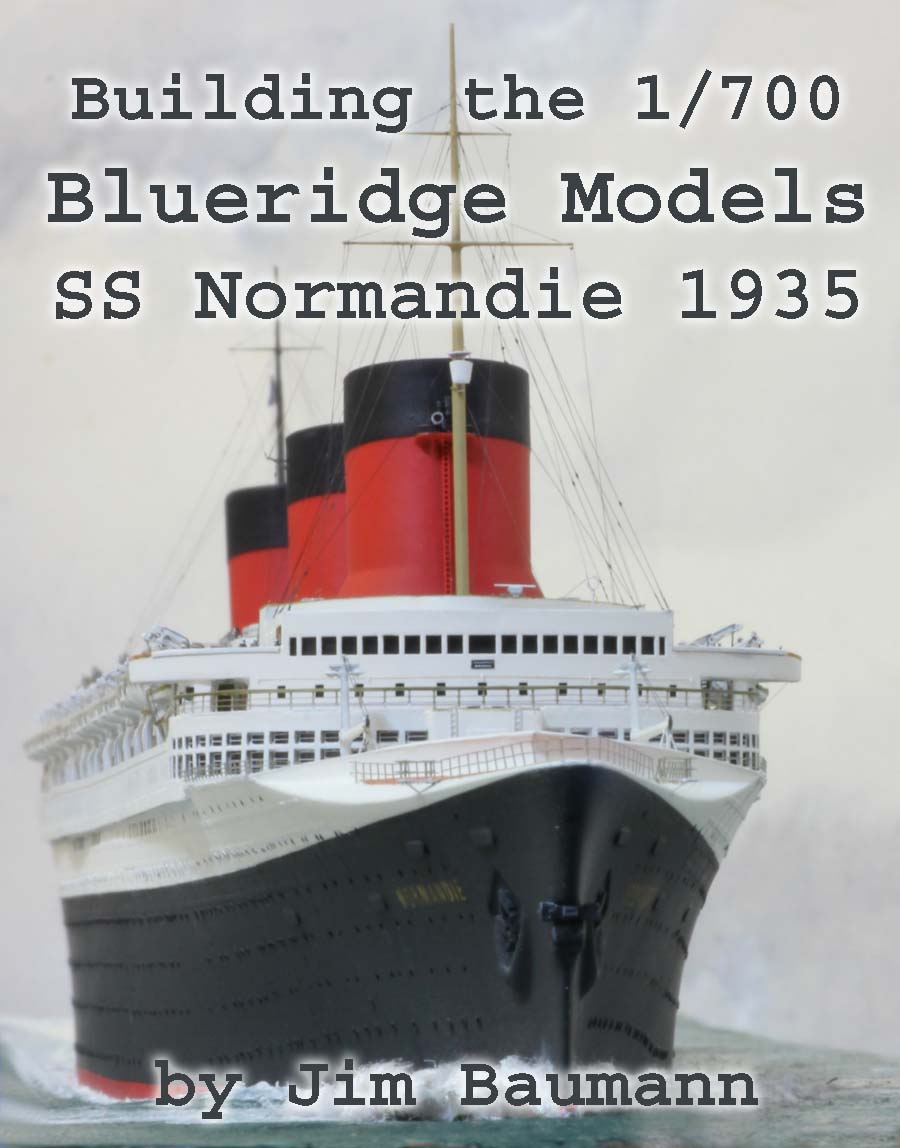

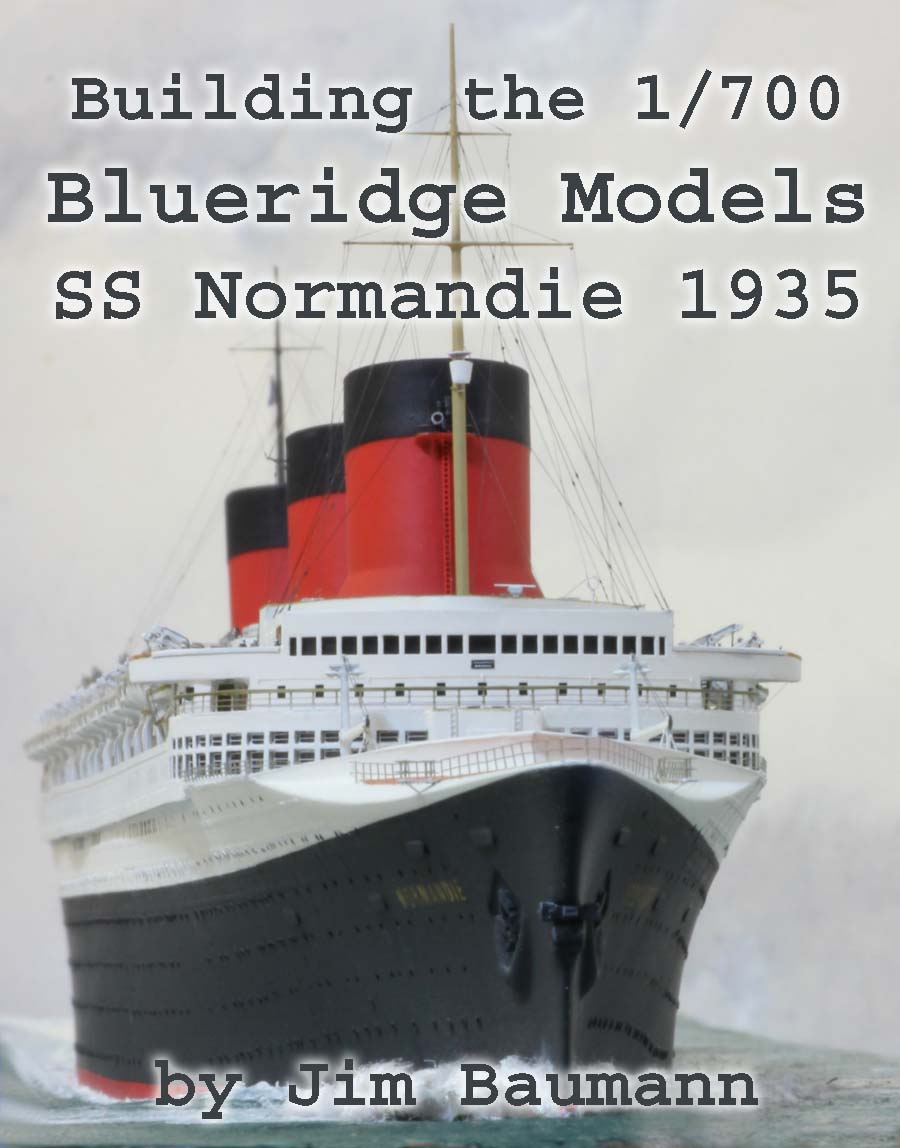

| The French superliner SS Normandie of the French Line (

CGT) entered service in 1935, at 1029 feet long she was widely regarded

as being both revolutionary and radical in her appearance, featuring wide

open uncluttered deck spaces not encumbered by ventilation equipment and

water tanks.

Her clean smooth-looking hull and superstructure, her large aero-foil shaped funnels and hollowed clipper bow made her an immediately recognizable and distinctive form, instantly rendering all competitors as looking old-fashioned. Her glamorous modern exterior cloaked an advanced construction within , she was and remains to this day - the largest and fastest Turbo-Electric powered ship ever built. With her then revolutionary bulbous bow she was able to achieve and maintain Blue-Riband capturing speeds exceeding 30 knots averaged for the entire Atlantic crossing with a considerably lower fuel consumption than any of her transatlantic shipping rivals. Normandie's legendary interiors were up the minute 'spirit-of-the age' Art Deco, popular with the glamorous and famous, numbering Marelene Dietrich and Clark Gable among many contemporary celebrities. In 1939 the ship was in New York ; with the fall of France in 1940 she remained there-- until impounded by the US Government , re-named USS Lafayette with a view to convert her to use as a troopship, which entailed all the luxurious interiors, statues and carvings to be removed into storage . During these works she tragically caught fire, in the efforts to douse the flames with water from the Firefighting ships ultimately causing her to capsize at her berth on Pier 88. The successful bringing back upright and re-floating was an epic and impressive effort; however the machinery was ruined and by that stage she was surplus to the required war effort and was scrapped in 1946. Building the model: After decaded of much hoping, dreaming and clamouring by ship model-makers worldwide wishing for a model of the iconic Liner Normandie- in any scale.......after all that long waiting...therein lies the irony …. that at almost the same time , two resin model kits of Normandie were released, in 1/350 scale by OMK models and 1/700 by Blueridge models. This kit by Blueridge models in 1/700 scale was released with much anticipation on my part , it came well presented in a fine padded box , and at first sight promised very much. The kit was reviewed here at Modelwarships.com and on the whole the review was positive. My build of the model occupied two and half years (!).Much of this time was spent in trying improve , refine, sharpen up detail and make more accurate and correct items.I decided on a no-compromise approach to this build, to try and create the best model that I could--==\> as I was only going to do it once! In my quest for as good a model as I can possibly make; my work-effort, frustration, time and financial thresholds are usually quite high though in this instance, I probably went too far in almost every aspect! This in itself brought about issues and challenges --the solutions I reached thereto may not for everyone . This proved to be a tall order on my part, as well as for my " support team " of PE designing and 3D printing. The full version of the process of building this model can be read right HERE at MW.com - fully illustrated My feeling is this kit was produced to be available at an affordable price. More inspection of photos and better research ( lifeboats, portholes/windows/waterline/decking/) re-fining the 3-D print master, more pre-resin cast master finishing, better and sharper quality moulds and casting would have been justified a higher starting price . I must stress however , that I would have been happy to pay more than

twice the purchase cost if the kit had been 25 % better ... The fact

is that Blueridge Models must be_commended highly_ for tackling this model

in kit form—and whilst there was much to improve it is nevertheless a valiant

effort. Therefore my thoughts and observations must be viewed within these

parameters.

_*As short illustrated summary of the main challenges overcome*_ |

||||||||||||||||||||||||||||||||||||

| The kit castings all featured a very much over-scale rendering of deck-planking (on a ship with such prominent uncluttered decks -- this is an issue to consider) |  |

|||||||||||||||||||||||||||||||||||

|

I resolved this ( to my satisfaction ) - by making all new decks, using PC created printed paper decking,with all deck plank butt ends removed and the caulking lines rendered in brown rather than black |

|

|||||||||||||||||||||||||||||||||||

|

Making all my own pattern templates for every single piece of deck, using post-it notes and tape to create the intricate shapes and allowing for the larger and different sizes where all edges and resin features had been cut away |

|

|||||||||||||||||||||||||||||||||||

|

2) I felt that the kit concept of letting dozens individual small sections of PE brass windows into the cast resin apertures was unlikely to get the seamless sharp and crisp rendition with perfect repeatability and clean demarcation of windows - white on black - that I desired. |

|

|||||||||||||||||||||||||||||||||||

| My solution of a full length PE overlay ( initially in brass and finally in stainless-steel) was completely satisfactory in creating the sharp edges and look that I craved ..... |  |

|||||||||||||||||||||||||||||||||||

| I must stress that this created a whole raft of new problems... _which were all of my own making _. This was caused by the differential rates of thermal expansion of the metal overlays and the resin hull beneath... I was unable to prevent the resin expanding and contracting faster, and at a greater extent than the stainless-steel metal overlays; Despite exploring all avenues of adhesives and temperature, it does appear that there is no beating the basic laws of physics ! I was able to prevent this from being a complete total-loss catastrophe, by _controlling the local temperature environment_ of the model and thereby controlling the relative expansion and contraction simply by permanently placing a full length electric heating mat underneath the 'sea-base' of model. This heating mat is controlled by a thermostat so as to neutralise the influences of ± ambient temperature variations. …...It may be.... that this was perhaps a step to far to gain sharp window outlines.?! | ||||||||||||||||||||||||||||||||||||

| The portholes were mostly in the correct place but some were of the wrong size and in the instance of all below-promenade-deck overhang windows, the incorrect shape . |

|

|||||||||||||||||||||||||||||||||||

| This combined with many of the castings being somewhat " soft " , especially on the bridge and superstructure castings |  |

|||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||

| and with the 3-D printed master printing 'step lines' being in parts prominently visible making a lot of extra work that could have been resolved at the design and pre-casting stage for a better end result. |  |

|||||||||||||||||||||||||||||||||||

| As the porthole frames raised edges on this ship were visible when viewed from ahead--I made over 1200 or differing sizes of 'rings' of thin wire, so as to be able to end up with 840 usable items these were flattened between hard surfaces and glued in place over the adjusted size apertures with varnish |

|

|||||||||||||||||||||||||||||||||||

| The model was cast with a separate lower hull, the split of which -in

my opinion after measuring and viewing photos was NOT at the waterline

but at the top of the red underwater antifouling line, therefore I think

that for a a waterline model the hull was to shallow.

I cured this by gluing around the entire lower perimeter off the hull-casting a substantial styrene square-block strip to allow the model to 'sit' in the water with the correct amount of red showing above the waterline |

||||||||||||||||||||||||||||||||||||

| The Normandie had a very distinctive pattern of reinforcing strips

straddling the black and white areas of the midships hull sides ,visible

in photos of the ship

All forms and sources of PE metal strip were way to thick, ergo over-scale to reproduce these. I used to metal foil tapes in 0.3, 0.4 and 0.5mm widths , as used in fingernail decor. These metallised tapes have very clean sharp edges giving the desired finesse. |

|

|||||||||||||||||||||||||||||||||||

| My kit suffered from a notably warped hull and main supstructure casting; _*most commendably *_these items were replaced immediately by the manufacture. However every one of the cast deck-parts were 'dished' and all of them had to be filled to be level--before scraping off all the cast decking and raised edges. | ||||||||||||||||||||||||||||||||||||

| The funnels were beautifully shaped, however all the castings showing notable signs of contraction hollowing ( waisting ) and needed repeated filling and fairing to gain the desired flat plane shapes |

|

|||||||||||||||||||||||||||||||||||

| The lifeboat castings at first sight looked OK-- but they were all discarded as they were rather incorrect. On the real ship, the lifeboats had a smaller boatst nested inside, the coamings of which were raised were above those of the larger boat. Both these boats had one overall cover. I commissioned a set of 3D printed boats of the correct sizes with the nested boat, the rudder, skegs and propellers as well as the canvas and tie-downs rendered.. |

|

|||||||||||||||||||||||||||||||||||

| The photo etch that was supplied in the kit was brass; much of it was

pretty good and usable, However-- on the Normandie all the railings- stanchions

and rails were silver grey. As well as differing types of wooden handrails

on the top,( which I had made in PE) the number of horizontal bars varied

in number pending on the railings position on the ship.

As these differing lengths and heights were not reflected in the PE – I commissioned some custom A4 frets of Nickel- Silver railings, so as to approximate the colour of the railings without adding the thickness of painting, thereby keeping it as fine as possible so to accommodate all the variants of railing sizes , heights and spacings |

|

|||||||||||||||||||||||||||||||||||

| The supplied cast davits and the PE brass arms whilst the correct outline

did not reflect the construction of the real thing

The davits were made up of separate PE items from my A5 PE frets, the arms being double layered back to back, assembled on a Blu-tack jig. |

|

|||||||||||||||||||||||||||||||||||

| The prominently visible kit life-raft stacks and the life-boat winches were somewhat soft cast in addition to being not quite the right shapes, therefore these were replaced with custom-3-D printed items |

|

|||||||||||||||||||||||||||||||||||

| The very large and distinctive NORMANDIE lettering between no 2 and No 3 funnels -supplied as flat brass on the kit PE fret was re-made in stainless steel relief etched PE. |  |

|||||||||||||||||||||||||||||||||||

| In conclusion, the model as now completed--does actually

look like the real Normandie appears to look in photos , and despite the

protracted build time, problems, challenges encountered and overcome, I

am quite pleased with the model.

It was a fascinating journey of intensive research in may areas, some of the plans were found to, at best wanting more detail, at worst some areas of the plans were actually an amalgam of pre-and post re-fit. As photos tend to tell the absolute truth, I bought a lot of books and obtained some private images from collectors around the world to assist in building the model. All of the custom PE and 3-D printing works I commissioned can be made available to my fellow modellers if they wish to tackle this model. I used many of the wonderful images spread across many books, as well as some very fine on-line resources as well You-tube black and white as well as early colour film.

|

||||||||||||||||||||||||||||||||||||

Bibliography:

|

||||||||||||||||||||||||||||||||||||

More

of Jim Baumann's work.

Updated 7/7/2021

© ModelWarships.com