| Plating is one of the most

challenging ship characteristics to replicate in miniature form. |

|

| Three major factors contribute to this challenge.

One factor is the scale thickness. It is extremely difficult not to overdo

the thickness of the plating. Paper, litho plate, and sheet styrene all

seem to overwhelm the model, especially smaller scale models.

Another factor in model plating is compound curves.

Ship hulls are complicated, three-dimensional shapes. The plating process,

therefore, is labor intensive, with results not always satisfactory. A

third negative aspect of plating by conventional techniques is whether

or not the material used will adhere to the hull. Gluing dissimilar materials

is unacceptable to most modelers' standards. Sooner or later the materials

will separate due to the different rates of expansion and contraction,

especially on areas as large as a model ship hull.

These three factors contribute largely to the absence

of hull plating on model ships. Dissatisfied with the results provided

by known plating techniques, I sought a better process. While removing

a mask from a model that had been painted, I studied the small ridge of

paint caused by the tape separating the colors. It seemed feasible that

I could control this ridge and produce the quality of plating I desired. |

| MATERIALS |

|

The following materials are needed: #600 wet or

dry sandpaper; Dupont 30 S Platinum Grey Hi-speed primer; Dupont 36085

Lacquer thinner; Dupont 30 S Platinum Grey Hi-speed primer; Dupont 3608S

Lacquer thinner; Dupont 3919S Prep Sol Solvent; 3M Scotch Magic tape and

#0000 steel wool.

|

| STEP ONE Hull Preparation |

|

| I primed the surface of my completed hull, and finished

it smooth with #600 wet and dry sandpaper. Since the plating did not hide

any defects in the hull, I had to be sure all blemishes were sanded out

during the priming process. I prepared the hull as if I was going to add

the final color coat. |

| STEP TWO Layout |

|

It is critical that the plating layout is completed

precisely, With a soft lead pencil, I transferred plating lines to the

hull, being as accurate as possible. In order to accurately transfer

lines, I used a copy of the actual builders' plating plan (pictures of

the actual vessel were also helpful in complicated areas). In laying out

the plating, built it into the hull from aft forward, so that all joints

lap away from the forward movement of the ship. If the hull is correctly

shaped it should coincide with the plating plan. If you have problems with

the measurements not matching your hull, check your hull measurements to

identify the problem. |

|

| STEP THREE: Applying Inside Strake

Plating |

|

Often one line of plates or strakes will be an inside

run and those on either side will be outside runs, producing the joggled

effect. For joggled plating, the inside strakes are applied first. Since

only the butt joints show, only these are applied. I usually started at

the top and worked toward the keel completing two or three full runs (bow

to stern), and applying port and starboard runs at the same time, alternating

between sides.

I laid down a mask covering the outside strakes from bow

to stern, leaving the inside strake exposed. I masked off the butt joints

with the tape on the stern side of the line. Using an airbrush, I applied

two or three heavy coats of primer to the butt joint mask only. I did not

spray the entire area inside the mask; applying paint only to the area

of the butt joint mask, making sure to feather the paint away from the

mask. I applied paint to all butt joint masks of the entire strake from

bow to stern, and then proceeded to the next strake. |

|

| Note: Some areas, especially around

the stern, were somewhat tricky to mask because of the extremely sharp

compound curves. If 3M Scotch Magic tape won't conform to these small curves,

cut regular masking tape into thin strips for these areas.

As I finished one side of the hull, I applied paint

to the other side in the same manner. When I completed the second side,

I went back and applied two more heavy coats to the first side, and then

repeated it on the second side. This flip-flop technique in applying the

paint helped to keep the lacquer from attacking the glue on the tape. After

the paint had glazed over, I carefully removed the mask. The inside strake

was now completed on the entire hull.

Note: Think heavy when applying paint. It's difficult

to go back and mask off areas that do not have enough depth, especially

inside stakes. With an airbrush, it is almost impossible to apply too much

paint. The plating will be wet sanded later, so even when you think you

have too much paint, apply more. Allow the paint to fully glaze over (approximately

thirty minutes to one hour); then remove the tape mask.

After 24 hours, I cleaned up any tape residue left

from the mask with Prep-Sol and a cotton swab. I lightly dry sanded the

butt joints with #600 wet or dry sandpaper. I paid special attention to

the area around the butt joint. If you try this,

you should have a crisp edge, about the thickness of cellophane on

a pack of cigarettes, that feathers away no more than 1/4" toward the bow. |

| STEP FOUR Applying Outside Strake

Plating |

|

| Under ideal conditions it usually takes lacquer

72 hours to completely cure. If you're careful, however, you should be

able to apply the outside strakes after 24 hours.

I masked off the outside strakes, applying the tape

to cover the inside butt joints. Applying this mask proceeded fairly quickly,

as the corners of the butt joints were a guide for the tape. The tape just

touched the corners or be set back just a little, exposing a small portion

of the butt joint corner. The result was a mask that exposed the full area

of the outside strake. |

|

| I marked off the butt joints on the tape with a pencil

(after the next step these lines for the joints won't be visible). Inside

the mask, I applied three to four heavy coats on the full length of the

hull, building up the strake (Illustration Two). I did the same to the

other side. As the paint glazed over, I applied another heavy coat or two

so that this area was sufficiently thicker than the application of paint

completed in step three (applying inside strake plating). Before this area

had dried, I gently scraped away the overspray on the tape exposing the

marks for the butt joints. By the time you have uncovered your reference

marks for the butt joints, the paint should have glazed over enough for

a light sanding.

I lightly dry sanded the outside strake leaving the

fine chalk on the hull. The chalk helped ensure that the tape for the butt

joints didn't pull off the paint. I applied the masks for the butt joints

with only enough pressure to hold the tape. I applied the paint to simulate

the butt joints, lightly feathering away from the mask as in step three

(Illustration Three). After this was completed, I carefully removed the

masks.

I waited at least 72 hours (one week is better),

and with Pre•Sol and a cotton swab, I gently removed the tape residue from

the plating. Steel wool and Pre-Sol were also helpful to remove the unwanted

residue. After I removed all residue, I lightly wet sanded the entire hull

with #600 wet or dry sandpaper. |

| SUMMARY |

|

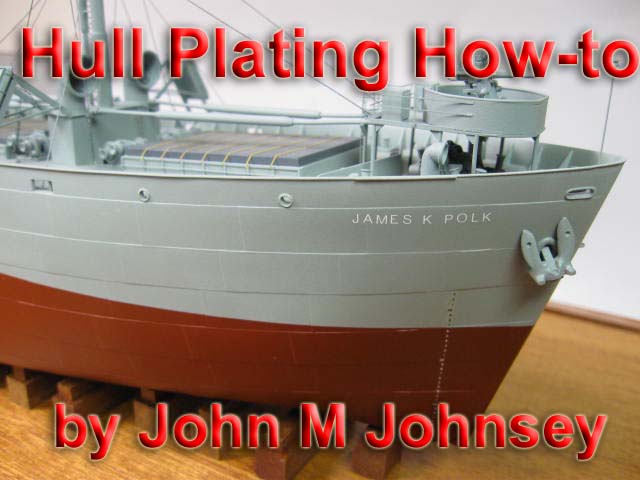

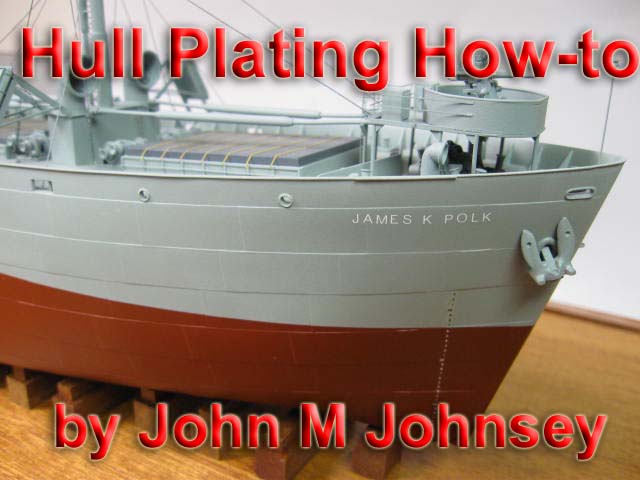

| The results of using this relatively quick technique are a beautifully

plated model with scale thickness hull plating and a material that will

last the lifetime of the model. Ship models with full hull plating are

impressive and capture much attention , especially from other modelers. |

|

| Additional Information on Hull plating

details |

|

| Some ship hulls had additional strengthening

features such as butt straps on critical areas of stress. From the models

I have built I have included this feature on the hull of ships that required

them. There are two design types I have seen used and these are a simple

rectangular strip and a more complicated saw tooth or zig zag pattern.

Both types are the width of the plate and the rectangular type is replicated

by simply masking off the area with a 1/16 inch gap between the mask left

to apply paint build up. (Note this is for a 1/192 scale model.) The zig

zag pattern had me stumped on how to make a mask that would "transfer"

this type of pattern to the ship hull. This was going to be a very time

consuming mask to cut and the destroyer model had several of these type

of butt straps. The solution came to me by accident. During the plating

process of the model my eye was caught by the serrated edge of the tape

as I was using it to plate the model. Eureka! It was a perfect pattern

that matched the saw tooth style of the prototype. The ends of the tape

as you cut with the serrated portion of the dispenser make a perfect pattern

for 1/192 scale models. Simply apply them with ends over the seams of the

plating with a 1/16 inch gap left between them for the paint build up.

A simple, effective, perfectzig zag butt plate. |